OEM Solutions

We Don’t Just Make Products — We Manufacture Solutions

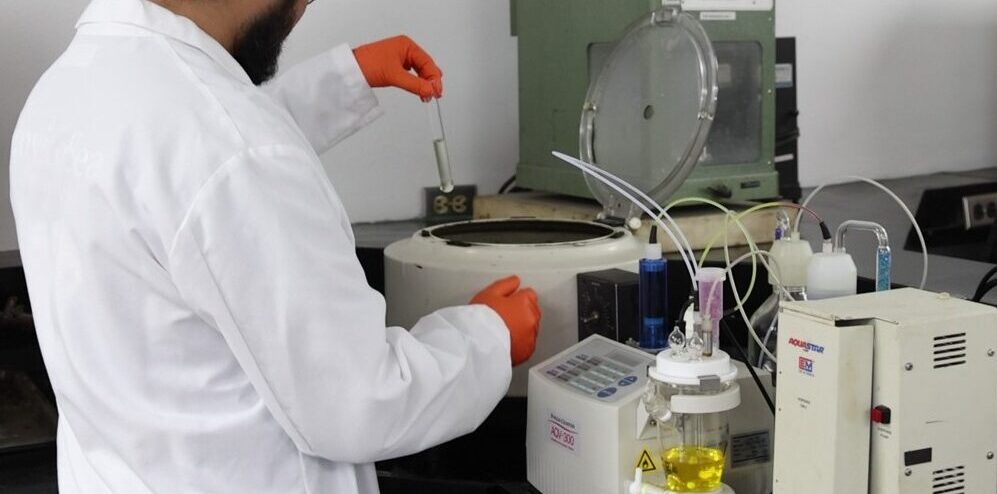

At Quadrant OEM, we turn complex manufacturing challenges into practical, high-performance solutions. With nearly 50 years of experience with aerospace and automotive products, and over 35 years with other specialty applications, our team delivers certified formulations and proven systems that enhance efficiency, improve quality, and reduce costs.

Built by Experts, Trusted by Manufacturers

Quadrant isn’t just another materials supplier, we’re a team of industry veterans who’ve worked where you work. Our sales and technical team have hands-on experience in the business segments we serve, giving us unique insight into your daily production challenges. When you work with Quadrant, you team up with people who understand the job, the process, and the importance of exceptional quality.

Experience That Delivers Results

We know that success isn’t theoretical — it’s measurable. Our polyurethane systems are designed to make your operation safer, faster, and more cost-effective, driving real results that improve your bottom line. From process optimization to waste reduction, Quadrant helps manufacturers unlock greater productivity and consistency at every stage.

Your Partner in Productivity & Progress

At Quadrant, we view partnership not as a step in the process, but as the foundation of success. By working closely with our customers, we gain a deep understanding of their objectives and challenges—enabling us to design and deliver polyurethane systems that meet precise performance and certification standards.

Let’s Build Something Better — Together.

Packaging Systems

Quadrant packaging foams deliver high-quality protective solutions tailored to your specific reaction and protective needs. Each of our formulations are carefully engineered to adapt precisely to the contours and voids of your molds or products, ensuring your merchandise is effectively protected against potential transit damage resulting from impact, shock, and vibration.

Manufactured from expand-in-place polyurethane, our packaging foam provides exceptional resilience and ease of use. Its lightweight composition not only enhances user convenience but also contributes to lower transportation costs compared to alternative packaging options, making it a cost-effective and reliable choice for safeguarding your shipments.

In addition to our advanced foam systems, we offer a comprehensive line of polyurea products designed to complement and complete your production process. We encourage you to consult with your sales representative to learn more about our full range of polyurea solutions and how they can be integrated into your manufacturing operations for optimal results.

Doors & Windows

Quadrant’s window foam solutions are specifically formulated to fill vinyl, fiberglass, aluminum, and steel extruded lineals. The Q2L window system stands out due to its low density and high flow-rate, which ensures minimal cell pressures throughout the expand-in-place foaming process. This combination of features effectively eliminates the risk of void formation and prevents damage or warping of cavity walls, supporting a smooth bending process for window manufacturing.

Furthermore, the high flow rate of Q2L reduces the amount of product needed to fill a typical lineal, offering efficiency and cost savings when compared directly to competitor products. Q2L foam is user-friendly, produces no odor, and is Green Guard certified, making it an ideal addition to any production line. Its ease of use and reliable performance make Q2L a favorite among line staff, streamlining operations and supporting environmental responsibility.

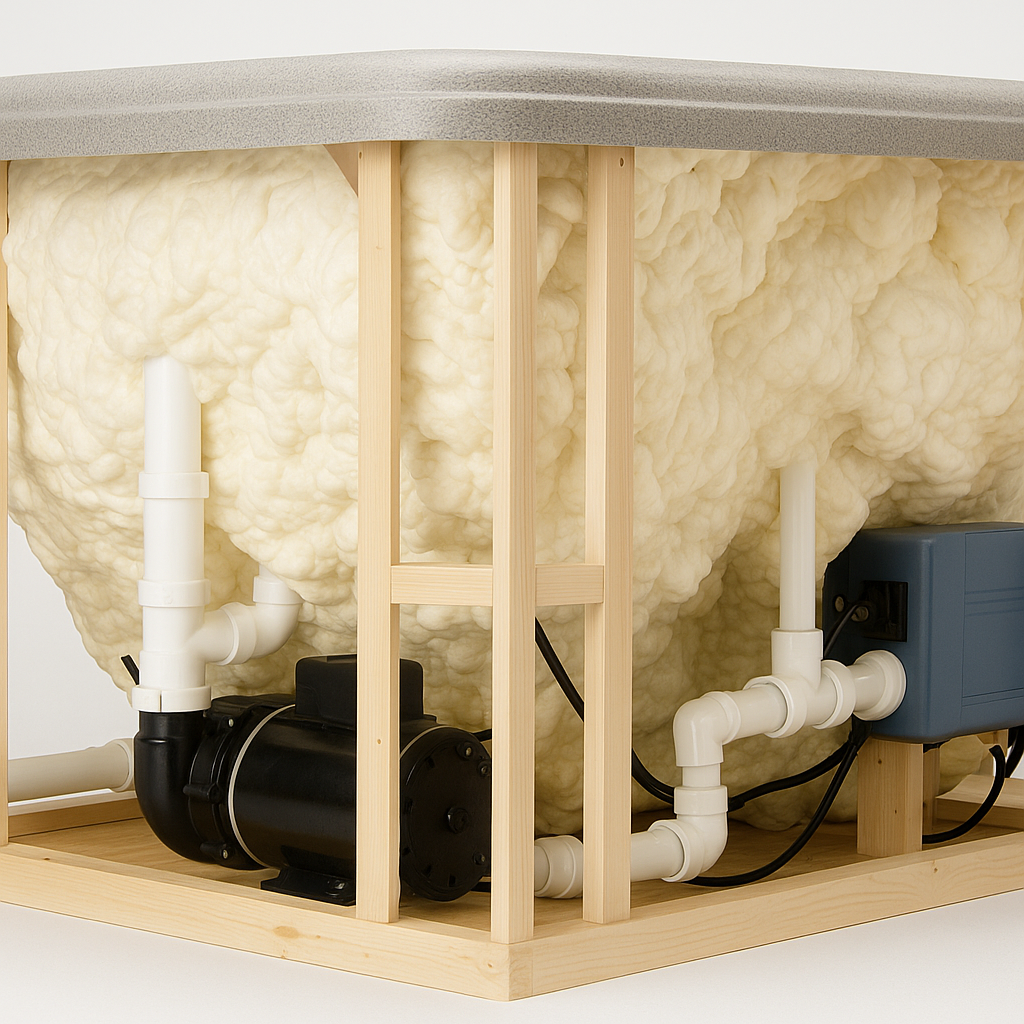

Spa & Hot Tub Foam Systems

Quadrant spa and hot tub systems feature specially designed polyurethane formulations that are tailored to meet and exceed the specific reaction profile requirements for your production lines. Our approach emphasizes customization, ensuring that each system is efficiently matched to your manufacturing needs. Whether you require complete cavity filling or targeted spot foaming to mechanically secure key components, we have a perfect fit for your production line. By selecting our individually customized foam systems, you will benefit from both time and cost savings throughout your production process. Our products are GREENGUARD certified, user-friendly, and characterized by low-odor, affirming our commitment to environmental responsibility and indoor air quality.

Quadrant spa foams deliver high insulation values and contribute to the structural strength of your spas. Their “spot welding” capabilities enable effective mechanical fastening of vital parts, while their resistance to water and moisture absorption ensures long-term durability and protection. Overall, these systems provide reliable insulation, structural reinforcement, and moisture protection for spa and hot tub applications.

In addition to our advanced foam systems, we offer a comprehensive line of polyurea products designed to complement and complete your production process. We encourage you to consult with your sales representative to learn more about our full range of polyurea solutions and how they can be integrated into your manufacturing operations for optimal results.

Geotechnical

At Quadrant, we manufacture high-performance polyurethane foams engineered specifically for the geotechnical industry. Our foams are designed to improve ground stability, fill voids, stop erosion, and provide long-lasting structural support in challenging soil conditions. By replacing heavy traditional materials, our lightweight foams reduce load stress on underlying soils while maintaining exceptional compressive strength and durability. Whether stabilizing foundations, supporting pipelines, or controlling water infiltration, our solutions offer fast, efficient, and environmentally responsible results with minimal site disruption.

Choosing Quadrant means gaining a partner with deep technical expertise and a commitment to performance. Our foams are water-resistant, non-reactive with soil and groundwater, and are formulated for consistent expansion and density across variable conditions. They cure quickly and can be applied in tight or remote areas, which saves both time and labor. From initial consultation through on-site support, our team works with you to deliver a dependable solution that improves safety, efficiency, and long-term stability for every project.

Concrete Lifting

Quadrant provides professional-grade polyurethane foams engineered for slabjacking, the modern and efficient solution for lifting and leveling sunken concrete. Our foams expand beneath the surface to fill voids and raise slabs back to their original position, restoring safety and functionality without the mess or downtime of traditional mudjacking. Ideal for driveways, sidewalks, warehouse floors, bridge approaches, and more, our high-density formulations deliver fast results that stand the test of time.

Partnering with Quadrant means more than just access to advanced materials, it also means gaining a technical ally. Our team offers decades of experience supporting contractors and engineers in optimizing foam performance for a wide range of site conditions. Our polyurethane systems are lightweight yet strong, water-resistant, and environmentally stable, ensuring permanent results with minimal disturbance to surrounding areas. Backed by expert support, consistent quality, and proven field performance, Quadrant helps you complete every lift with confidence, precision, and long-term reliability.

Get Started Today

At Quadrant, we specialize in delivering polyurethane solutions that elevate manufacturing performance across industries—from packaging and dock floats to pipelines and specialty applications. Backed by hundreds of successful collaborations, our team brings proven expertise in making products lighter, stronger, and more durable while optimizing production efficiency. Ready to transform your process?

Contact us today to discover how Quadrant can help you achieve smarter and stronger results.